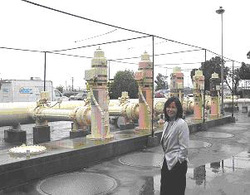

City of LA Pump Station Rehabilitation Projects – Terminal Way and Highbury Pump Stations

ProjectLine assisted with electrical and mechanical rehabilitation design for Terminal Way Pump Station (subconsultant to Brown and Caldwell), and for Highbury Pump Station (subconsultant to Atkins Global). The Terminal Way project included replacement of pumps, motors, air conditioning (AC) equipment, backup generator, and various valves and gates. ProjectLine’s scope included preliminary design for AC improvements, and final design for electrical and controls upgrades. The Highbury project also included replacement of pumps, motors and backup generator, and ProjectLine’s scope included electrical and controls design. ProjectLine provided assistance with City Plan Check approvals, and follow-on construction-phase engineering services.

Sepulveda Pressure Control Station and Hydroelectric Plant, Metropolitan Water District of Southern California (MWD)

Assisted with preliminary design of replacement for existing 600 cfs (peak flow) pressure control station (PCS) and 8.6 MW Hydroelectric Plant (HEP). Built in 1972, the PCS is at risk of seismic liquefaction, leading to concept for PCS replacement on adjacent stabilized site. Existing PCS drops water from peak upstream HGL of 1267’ to downstream HGL of 850’ using ten 24-inch sleeve valves. Key considerations in replacement PCS include sleeve valve selection for robust anti-cavitation operation over expected range of conditions, mitigation of hydraulic transients (in event of turbine trip, etc.) with vacuum/pressure relief, and control strategy for flow transfer between HEP and pressure control valves. Existing Pelton-type HEP operating envelope ranges between 100 and 400 cfs. ProjectLine tabulated flows and available head for Francis-type HEP replacement on new site using water system demands, coordinated with turbine vendors for concept, estimated HEP replacement costs, and projected power generation revenue. The project also included preliminary concept for 100 cfs pump-back stations at both Venice and Sepulveda PCS sites for moving water west in MWD’s distribution system during drought conditions. The project is on hold pending investigation of soil stabilization and site options.

City of Los Angeles BOS and BOE – Hyperion and Tillman Advanced Water Purification Facilities (AWPF)

ProjectLine assisted with preliminary designs of mechanical, electrical and control systems for design-build AWPF facilities at the Hyperion and Tillman Water Reclamation Plants. The 4 mgd Hyperion AWPF includes membrane bio-reactors (MBR), reverse osmosis (RO) and advanced oxidation process (UV plus hydrogen peroxide). For Hyperion AWPF, ProjectLine’s role included electrical and controls, and mechanical design for the product water storage and pumping. Product water for the Hyperion AWPF will be used for Title 22 applications at the adjacent LAX airport. The 25 mgd Tillman AWPF includes biologically active filters, microfiltration, disinfection conversion, and AOP. Tillman AWPF water will be used for Title 22 applications and for spreading facilities.

City of Los Angeles, Albion Riverside Park

ProjectLine provided electrical design for site improvements on this Proposition O project as a subconsultant to Tetra Tech. Design for the 6-acre site included BMPs to improve water quality of stormwater prior to discharging to the Los Angeles River, and upgraded outdoor sports fields, park areas, and parking areas. The project provided multiple benefits to the neighborhood by creating visual linkages to the Los Angeles River and linkages to other projects referenced in the Los Angeles River Revitalization Master plan. ProjectLine’s electrical design included innovative LED lighting for sports fields and park areas based on photometric modeling, with PC-based programmable lighting controls, and meeting the latest City lighting standards.

LADWP - Owens Lake Dust Mitigation Controls Project

Owens Lake’s ponds, lateral shallow flood, and managed vegetation require water for dust mitigation in compliance with environmental mitigation agreements. The Lake’s water use fluctuates throughout the day due to automated schedules that run over 150 shallow flood laterals and over 50 managed vegetation blocks. There are also numerous ponds filled by large submains throughout the Lake. Water supplied for these different dust mitigation measures is supplied from the Los Angeles Aqueduct and the Lower Owens River Pump Station (LORPS) through a mainline pipe that transects Owens Lake. ProjectLine developed control strategies for the implementation of a new Lake Flow Stabilization and Pressure Control tool. The strategies were implemented on Allen Bradley ControlLogix PLCs communicating via Controlnet. ProjectLine’s scope included developing bench and on-site test procedures, and assisting with operator training. ProjectLine was a subconsultant to CDM for the project.

LADWP – Aqueduct Plant UV Disinfection Facility, and LAR UV Disinfection Facility

ProjectLine provided electrical, instrumentation and control systems design for the new 600 million gallons/day UV Disinfection Facility for LADWP’s Los Angeles Aqueduct Water Treatment Plant. ProjectLine was subconsultant to ARCADIS (formerly Malcolm Pirnie) for the project. The facility has 14 UV reactors, each with a maximum flow of 60 MGD, controlled by an Allen Bradley PLC provided by the reactor manufacturer. A redundant Controlnet network links each local control panel to a master PLC/ HMI in the facility control room. The master PLC communicates with both the Plant Control Room SCADA, and the City’s LAWSDAC. ProjectLine also provided point to point wiring diagrams, and cable and conduit schedules in accordance with LADWP design standards. LADWP is responsible for installing the equipment.

Projectline subsequently provided similar services for a second UV disinfection facility treating water from the LA Reservoir prior to entering the City water distribution system. ProjectLine was subconsultant to the MPAC Consulting team for this project, which is a joint venture between Arcadis and Carollo Engineers.

Projectline subsequently provided similar services for a second UV disinfection facility treating water from the LA Reservoir prior to entering the City water distribution system. ProjectLine was subconsultant to the MPAC Consulting team for this project, which is a joint venture between Arcadis and Carollo Engineers.

Preliminary Design of Stormwater Improvements, Los Angeles Department of Water and Power

ProjectLine evaluated four alternatives for re-routing existing storm drainage at LADWP’s Van Norman Complex to make room for construction of a new chlorine contact tank and related water treatment plant site upgrades. ProjectLine produced plans and profiles for the alternatives, and summarized recommendations in a preliminary design report. ProjectLine was a subconsultant to Northwest Hydraulic Consultants for the project.

LADWP – Adelanto PV Solar Generating Station

LADWP has a current program that will increase the amount of solar power installed in the City to 1.3 Gigawatts. As part of this program, Solarworld designed and built a 10MW PV generating station at Adelanto. 46,322 solar panels were required, spread over 42 acres. Installation was completed by LADWP.

ProjectLine was a subcontractor to Solarworld, providing the communications system design and integration. A fiber-optic network links RTUs, SEL protection relays, power monitors, inverters, and weather stations using DNP3 and Modbus TCP protocols. The SEL RTU will link to the local HMI and LADWP’s central monitoring system (LAWSDAC). ProjectLine’s scope included RTU configuration, bench and on-site testing and startup of the communications system. The station was bought on-line July, 2012. Construction cost was $48 million.

ProjectLine was a subcontractor to Solarworld, providing the communications system design and integration. A fiber-optic network links RTUs, SEL protection relays, power monitors, inverters, and weather stations using DNP3 and Modbus TCP protocols. The SEL RTU will link to the local HMI and LADWP’s central monitoring system (LAWSDAC). ProjectLine’s scope included RTU configuration, bench and on-site testing and startup of the communications system. The station was bought on-line July, 2012. Construction cost was $48 million.

MWD - Hayfield Groundwater Recover Facility

To augment water supplies during dry years, Metropolitan Water District of Southern California decided to build a groundwater recovery facility in the Mojave Desert adjacent to the Colorado River Aqueduct and the Julian Hinds Pumping Plant. A submersible pump in a 1000 foot deep well is designed to recover water from the Hayfield Groundwater basin at a rate of 3000 gpm. ProjectLine designed the electrical and instrumentation systems for the facility including 2 miles of 6.9kV overhead transmission line running parallel to a 230kV Blythe Energy transmission line. The distribution line was fed from new 6.9kV switchgear at the Hinds pumping plant and interfaced to the existing 6.9 kV substation switchgear supplying the twelve 9000 HP Hinds pumps. A 6.9/4.16 kV transformer and soft start at the well fed the 800 hp submersible pump. An above ground monitoring system provided data on water levels and pump conditions, including alarms.

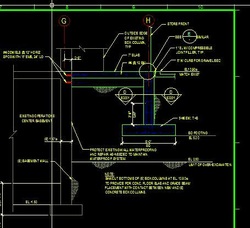

Castaic Lake Water Authority/MWD – Santa Clara Valley Foothills Pipeline Turnout

Projectline is providing electrical and instrumentation design services for a new MWD turnout to the Castaic Lake Water Agency as a subconsultant to Kennedy Jenks. A new turnout from the 200 inch MWD Foothill Feeder is being designed that includes a 48” isolation valve and magnetic flow meter in separate underground vaults. A new electrical supply is needed to provide the turnout loads. The flow meter is connected to a new AMR cabinet which connects by phone modem to MWD’s monitoring center. The local RTU is also connected to CLWA’s existing PLC cabinet close by.

Wastewater Treatment Plant Design – Confidential Client, Plastics Manufacturing

ProjectLine designed and provided equipment procurement assistance for a 0.5 mgd industrial wastewater treatment plant for a specialty PVC resin manufacturing plant. Designs included three process trains, each with inlet surge tanks, clarifiers, sludge holding tanks, plate and frame filter presses, effluent tanks, sludge and effluent pumps, and stormwater storage and pumping equipment. Auxiliary systems included storage and dosage pumps for coagulents, flocculents, hydrogen peroxide, and caustic (NaOH), related safety systems, sludge storage canopies, and compressed air and plant water utility systems. Sludge tanks included floating mixers and related tank attachments. ProjectLine provided civil, structural, mechanical and electrical/controls designs, and assisted with equipment shop drawing reviews for the project. The Owner served as general contractor for this project, and ProjectLine provided detailed piping drawings and databases for Owner purchase of piping, valves and appurtenances, including all flanges, gaskets, bolts, weld-o-lets, etc. The project included an extensive pipe rack system, and ProjectLine’s design included ladders and access platforms for access to valves. The electrical and instrumentation system was designed for a Class 1, Division 2 hazardous environment.

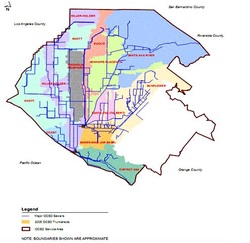

Metropolitan Water District of Southern California (MWD) On-Call Engineering Services

ProjectLine provided instrumentation and mechanical engineering, and CAD design support services for chemical systems upgrades to Skinner and Diemer water treatment plants as a sub-consultant to MWH. Projects added and/or replaced sodium hypochlorite, caustic, alum/ferric, ammonia, polymer and fluorosilicic acid systems. Skinner designs added and replaced a total of 56 chemical injection points for 520 mgd Modules 1 through 6 and a new 110 mgd Module 7 expansion. ProjectLine designs included sodium hypochlorite tank farm and chemical injection, chlorine ejectors and chemical injection, and pumped mixing for injection of alum/ferric and polymer. For the Diemer plant, ProjectLine provided mechanical engineering for preliminary design of sodium hypochlorite systems for future backup disinfection, basin chlorination and filter backwash chlorination, and for air compressors. Design services for the Diemer project included civil engineering and CAD services for a large site preparation project for the Oxidation Retrofit Project. Site preparation work included relocation of existing utilities located in the area of a future ozone generation building and ozone contactors.

ProjectLine also provided follow-on construction-phase engineering services including responses to Contractor questions, shop drawing reviews, on-site engineering support, and preparation of 12 Plant-Wide System Schematics for the relatively complex chemical and utility systems for the upgraded plant.

ProjectLine also provided follow-on construction-phase engineering services including responses to Contractor questions, shop drawing reviews, on-site engineering support, and preparation of 12 Plant-Wide System Schematics for the relatively complex chemical and utility systems for the upgraded plant.

Air Products and Chemicals Inc. – Fuel Cell and Hydrogen Energy/Fueling Station at OCSD

ProjectLine provided preliminary and final design, and construction management services, for installation of a fuel cell, hydrogen purification system, and hydrogen fueling station at Orange County Sanitation District’s (OCSD) Plant 1 in Fountain Valley, CA. ProjectLine provided services under contract with Air Products and Chemicals, Inc (Air Products), with Air Products providing equipment for this demonstration project. The project includes cutting edge technology for generating electricity, purifying and storing hydrogen gas, and fueling hydrogen-powered vehicles throughout Orange County and Southern California. This vehicle emissions reduction project was funded by the US Department of Energy, the California Air Resource Board, South Coast Air Quality Management District, Air Products, and the Orange County Sanitation District. ProjectLine provided civil, structural, mechanical and electrical designs for equipment installations and utility connections. Key safety considerations included compliance with NFPS 55 requirements related to storage and handling of hydrogen gas, and NEC requirements for classified areas. ProjectLine provided follow-on construction phase engineering services, including on-site management of subcontracted construction contractor.

City of Los Angeles Bureau of Sanitation – Venice Dual Forcemain

ProjectLine provide electrical and instrumentation design services for the Venice Pump Station Dual Forcemain Project as a subconsultant to Tetra Tech. The project provided a second 54 inch forcemain from this critical pump station to improve reliability and allow the existing forcemain to be temporarily removed from service when maintenance was needed. Both the new 54” and existing 48” forcemain were provided with new electric operated isolation valves and magnetic flow meters installed in underground vaults. The valves and flow meters were monitored at the pump station PLC, at the local HMI and the utility wide Transdyne HMI. New motorized gates, and gate intercom were added for improved pump station security.

Electrical Reliability Upgrades, City of LA Glendale Water Reclamation Plant

This project provided significant improvements to the reliability and flexibility of the Glendale Reclamation Plant’s internal electrical supply system. A new medium voltage (4.16KV) switchboard replaced an outdated existing switchboard and added bus ties for alternative medium voltage feeds. Similarly new low voltage (480V) bus-ties provided redundant feeders to critical process equipment. Three older delta-delta transformers were replaced with new star-delta transformers having resistance neutral grounded secondaries for improved safety. An initial site survey documented existing electrical conditions and provided the basis for the improvement recommendations in the preliminary design report. ProjectLine provided electrical engineering design services a subconsultant to Black and Veatch for this project.

Civil, Electrical and Mechanical Upgrade Designs, Orange County Sanitation District

ProjectLine provided electrical designs for replacement of five corroded 11KV pullboxes that form part of the medium voltage distribution system at Plant 2 located in Huntington Beach. The new boxes were designed to meet code and to be installed without disturbing the existing cables. The 11KV cables were tested by the Contractor both before and after box installation to ensure cable integrity was maintained. Another upgrade design task replaced existing secondary busways for ten substation transformers at Plant 1, located in Fountain Valley. Redesigned interfaces to the transformers and switchgear were needed for the new cableways. Safety and construction sequencing to avoid impacting process operations were important considerations in design of upgrades. ProjectLine also provided mechanical design for replacement of existing HVAC equipment at the end of its useful life, ADA upgrade designs for OCSD’s Plant 1 campus, preliminary engineering for expansion of the Purchasing Building at Plant 1, and civil/structural design for improvements to the Control Center at Plant 2.

City of Los Angeles – Project Management for Hyperion, Terminal Island, DC Tillman and Glendale Treatment Plants

ProjectLine managed and prepared civil and mechanical designs for upgrades and maintenance of the City of Los Angeles’ wastewater treatment plants. ProjectLine staff managed upgrades to a variety of systems including:

- Emergency oil cooling system for Tillman and Glendale Plant blowers

- Odor control system upgrades and biofilter tests for Hyperion Plant

- Dewatering polymer system for Hyperion Plant Centrifuge Facility

- Oxygen diffusion system for Hyperion plant reactor modules

- Sodium bisulfite dosing system for Terminal Island Plant

- Final tanks upgrade for Terminal Island Plant

- Direct steam injection sludge heating system for Hyperion Plant

- Channel aeration system upgrade for DC Tillman Plant, Channel #2

- Sludge Emergency Storage System (digester modifications for sludge storage) for Hyperion Plant, Digester Battery B

- Grit and Screening Upgrade for Hyperion Plant Headworks

City of Santa Ana – West Pump Station Upgrade

ProjectLine provided electrical and instrumentation design services as a subconsultant to Metcalf & Eddy for upgrades to the City of Santa Ana’s water booster West Pump Station.

Built in the early 1960s, the station included three 150 HP and two 100 HP pumps located adjacent to a 6 million gallon steel reservoir. The project replaced pumps, motors and electrical equipment at the end of its useful life, and added a new building to enclose the pump station and new electrical equipment.

The project also included MCC replacements for three existing well pumps located on the reservoir site, and relocation of site security equipment.

Built in the early 1960s, the station included three 150 HP and two 100 HP pumps located adjacent to a 6 million gallon steel reservoir. The project replaced pumps, motors and electrical equipment at the end of its useful life, and added a new building to enclose the pump station and new electrical equipment.

The project also included MCC replacements for three existing well pumps located on the reservoir site, and relocation of site security equipment.

Metropolitan Water District of Southern California (MWD), Weymouth ORP Design

ProjectLine provided mechanical and instrumentation engineering design and CAD services for upgrade of MWD’s 520 mgd Weymouth Water Treatment Plant from chlorine disinfection to ozone. Instrumentation design included over 80 P&IDs for ozone generation and related cooling water and chemical injection systems. P&IDs were developed using Bentley’s Plantspace software with an innovative, customized database application. Linking a database with equipment and instruments on P&IDs allowed for accurate and efficient development of instrument lists, I/O and equipment lists. ProjectLine prepared control loop descriptions and diagrams of network communication systems detailing integration with MWD’s existing SCADA.

ProjectLine designed rapid mixing systems for chemical additions, including six 3,500 gpm, 75 HP, VFD-driven centrifugal pumps with related mixing nozzles and chemical diffusers for alum, polymer and chlorine. Rapid mix designs included three large ultrasonic flow meters (in 15 ft x 13 ft box conduit) and isolation gates for connection to the existing treatment plant. ProjectLine was a subconsultant to Carollo Engineers for the project.

ProjectLine designed rapid mixing systems for chemical additions, including six 3,500 gpm, 75 HP, VFD-driven centrifugal pumps with related mixing nozzles and chemical diffusers for alum, polymer and chlorine. Rapid mix designs included three large ultrasonic flow meters (in 15 ft x 13 ft box conduit) and isolation gates for connection to the existing treatment plant. ProjectLine was a subconsultant to Carollo Engineers for the project.

Metropolitan Water District of Southern California (MWD) – Upper Feeder Gate Replacement Project

ProjectLine provided mechanical, electrical and instrumentation design for rehabilitation and replacement of 10 large, cast ductile-iron slide gates at 3 flow control structures on MWD’s Upper Feeder. Designs included 2 replacement gates and rehabilitation of 8 corroded gates in service since 1965, at facilities originally constructed in 1937. Critical need for reliability led to unique requirements, including plasma-applied zinc- metallizing coatings, solid stainless steel gate stems up to 82 ft long designed for actuator stall torque, and Limitorque SMB-2 and SMB-3 replacement actuators with remote control capability.

Designs provided for installation within a single 4-day shutdown window for MWD’s critical Upper Feeder. ProjectLine is a subconsultant to Black & Veatch for the project.

Designs provided for installation within a single 4-day shutdown window for MWD’s critical Upper Feeder. ProjectLine is a subconsultant to Black & Veatch for the project.

Technical Support to LADWP’s Solar Incentive Program (SIP)

ProjectLine provided strategic planning services as required to support LADWP’s renewable portfolio projects as a subconsultant to Black & Veatch. ProjectLine assisted LADWP in developing tools to more efficiently process LADWP's Solar Incentive Program data and customer reservation requests. Specific tools developed included:

- scripts to automate forms - creation, emailing and saving PDFs

- scripts to extract and store email addresses contained in email folders, and load to database

- scripts using AutoIT to extract data from PDF forms and store in Excel

- VBA code for mass email and mouse wheel disable function in Access form

- Excel macros with a view to semi automating SIP processes.

EAR Engineering – On-Site Chlorine Generation Systems

ProjectLine provided design-build engineering services for two on-site chlorine generation systems to replace use of chlorine gas for chlorination of potable water at Edwards Air Force Base. Systems included salt storage, rectifiers, sodium hypochlorite storage tanks, dosage pumps, flow metering and chemical injection. Systems also included aqueous ammonia storage tanks, chillers and dosage pumps for future conversion to chloramination. Engineering services were provided using innovative, fast-track design-build collaboration with the owner, construction contractor and equipment suppliers.

City of Ontario – Site Security Upgrades Project

ProjectLine provided design-phase and construction management for upgrades to security systems at City reservoirs 1, 2, 3, 7, 8, 9 and 10. Upgrades included vandal-resistant, visually attractive electric sliding gates, fences, and Supervisory Control and Data Acquisition (SCADA) equipment enclosures. Security enclosures included intrusion alarms to the City’s SCADA system. ProjectLine evaluated alternative security enclosures, fencing and gate materials, and assisted the City in selecting materials suited to City park locations of three sites. Upgrades also included motorizing three existing manual sliding gates at the Public Works Agency site. Sliding gates included security and safety loops, and card readers integrated with existing City security systems.

Caltrans Stormwater Best Management Practices (BMP) Evaluations

ProjectLine prepared two reconnaissance studies for Caltrans stormwater management program, each of which included a literature review and study report. The first study evaluated alternatives for stormwater disinfection as a potential new Caltrans BMP. Disinfection alternatives evaluated included anti-microbial filters, ozone, ultraviolet irradiation, and chlorination/ dechlorination, with anti-microbial filters recommended for further consideration as a Caltrans BMP. ProjectLine also prepared an evaluation of alternatives for more efficiently cleaning of existing approved Gross Removal Device (GSRD) BMPs. ProjectLine recommended pilot testing of pipeline pigging and waterjetting, and shaftless screw installations for cleaning of Caltrans’ Linear-Radial GSRD, which is a cylindrical well-screen used for trash removal. ProjectLine prepared conceptual design drawings for recommended GSRD and stormwater disinfection technologies.

Metropolitan Water District of Southern California (MWD) Rail Car Unloading Platform, Jensen Water Treatment Plant

ProjectLine provided structural, mechanical and electrical engineering design services for Jensen Water Treatment Plant’s caustic tank farm rail car unloading platform, as sub-consultant to MWH. Project replaced two existing fixed platforms with one 150-foot long platform with four track-mounted gangways. Platform design provided for unloading of up to four rail cars at the same time without uncoupling and positioning of rail cars. Design included safety eyewash and showers, lighting, and page/party and security camera systems. Rail car unloading platform design was coordinated with existing railway right-of-way, and within a larger tank farm project, which included a new containment structure and tank farm roof.

City of Ontario – Reservoir Repair Contract Management, Construction-Phase Engineering Services

ProjectLine provided contract management services for repairs of two City of Ontario water supply reservoirs, 0.375 and 2.0 million gallon Reservoirs 5 and 6. ProjectLine staff prepared the project scope of work, cost estimates, construction schedule, evaluation of bids, and recommendation for contract award. Services also included contractor field oversight, Quality Assurance/Quality Control monitoring, review of contractor submittals, and technical evaluations of repair alternatives. Repairs implemented include sealing approximately 3,000 linear feet of cracks in the concrete walls and slabs of the reservoirs, recoating corroded interior roof supports, and repairs to concrete voids and spalls. ProjectLine evaluated alternative repair methods, recommending an advanced, very-low-viscosity gravity penetrating epoxy sealant for more cost-effective repair of selected cracks. Alternative repair methods allowed completion of added work within original project budget and schedule.

South Orange County Wastewater Authority (SOCWA) – CAD Standards and P&ID Development Services

ProjectLine assisted SOCWA with development of CAD standards for use by consultants that produce designs for SOCWA’s treatment plants, pipelines and related facilities. These CAD standards will improve SOCWA’s ability to manage and maintain accumulated CAD data, and facilitate sharing of information with member agencies. CAD standards include electronic CAD file format requirements, layering standards, nomenclature and file naming conventions, and graphic standards. CAD standards were then applied to development of P&IDs for key SOCWA wastewater treatment unit processes, to provide an understanding of the processes and better document process controls.

Collection System Pretreatment Cost-Benefit Evaluation, Orange County Sanitation District (OCSD)

ProjectLine evaluated costs and benefits of upstream collection system chemical addition for odor and corrosion control. The goal of the evaluation was to quantify costs and benefits thereby providing for well-informed level of service decisions for OCSD’s collection system. OCSD’s collection system includes 11 major trunk sewers and 8,700 manholes valued at over $3 billion, and approximately $24 million per year is spent for asset rehabilitation and replacement. OCSD has been addressing collection system odor and corrosion concerns since 1985, and has since expanded and refined these efforts to include chemical pretreatment in four of its eleven interceptors that have the greatest capacity to generate hydrogen sulfide. In 2009, OCSD’s expenditures for chemicals, equipment, and related pretreatment program services were approximately $5 million per year, impacting 30% of OCSD’s collection system assets. The cost-benefit evaluation compared OCSD’s chemical expenditures to the cost of deferring anticipated maintenance / replacement costs for the impacted infrastructure assets. The conclusion is that at high levels of hydrogen sulfide (e.g. > 100 ppm vapor-phase), generally upstream chemical pretreatment in the collection system is expected to be economically justified. The project also included a benchmarking survey among three other large municipal agencies that use similar chemical pretreatment methods (LACSD, San Diego, and Phoenix), with the conclusion that OCSD’s approach to chemical pretreatment is similar to that of comparable agencies.